Plant Varieties Developed |

Animal Breeds Developed |

Animal Breeds Registered |

Trademarks |

Technologies Developed |

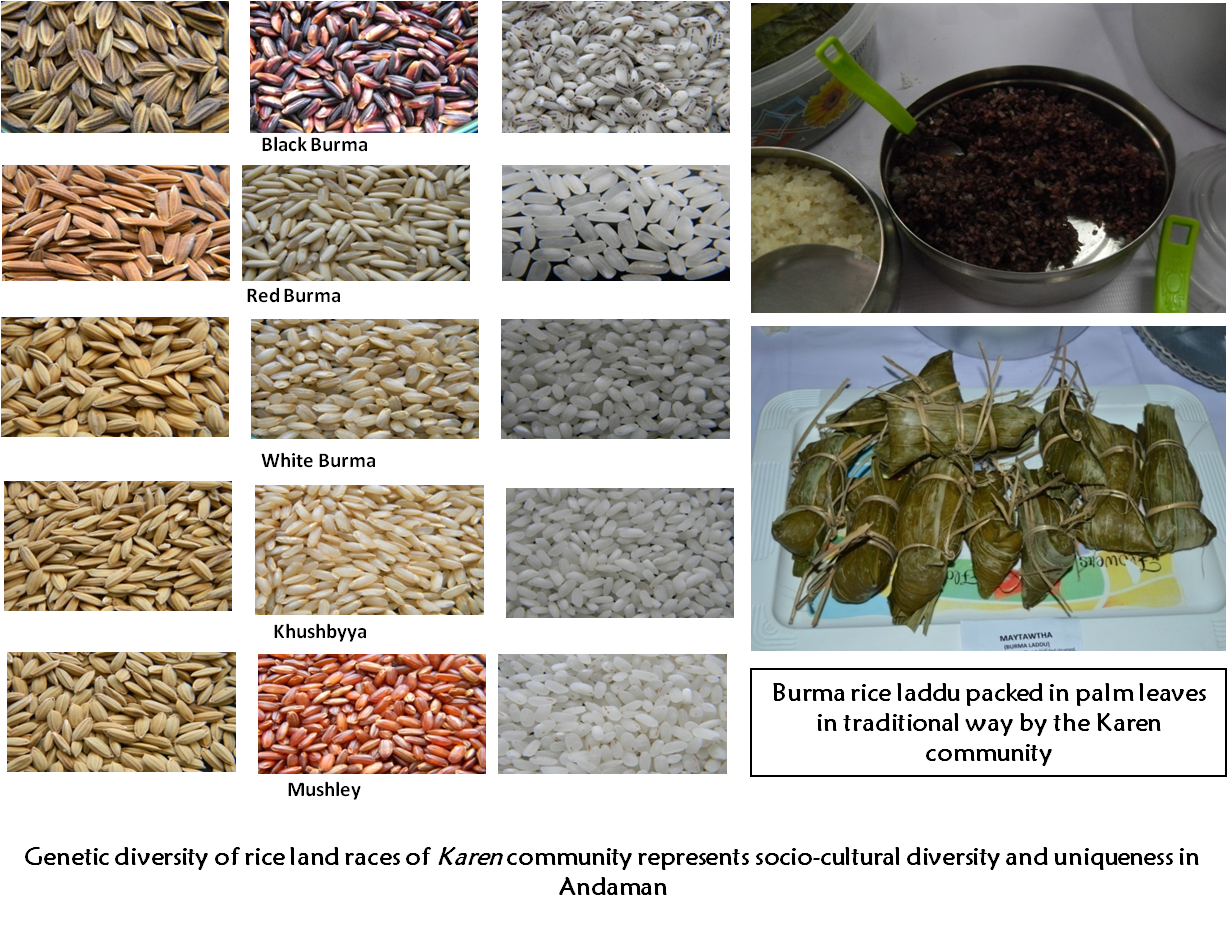

Varieties Registered For Plant Genome Saviour Community Award |

Post-Harvest Technologies |

CARI DHAN1

|

Plant height (cm) | : 115 |

| Panicle length (cm) | : 24 | |

| Days to maturity | : 120 | |

| No. of tillers/plant | : 6 | |

| Grain type | : Long slender | |

| Yield | : 4.5 t/ha | |

| Biotic Stress | : Tolerant to BLB and Stem Borer | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : Rain fed lowland normal soils of Andaman & Nicobar Islands. | |

| Innovators | : PK Singh, Krishna Kumar, TVRS Shrama, Ajanta Birah, RC Srivastava |

CARI DHAN2

|

Plant height (cm) | : 110 |

| Panicle length (cm) | : 25 | |

| Days to maturity | : 121 | |

| No. of tillers/plant | : 6 | |

| Grain type | : Medium slender | |

| Yield | : 5 t/ha | |

| Biotic Stress | : Tolerant to Bacterial Blight and Stem Borer | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : Rainfed lowland normal soils of Andaman & Nicobar Islands. | |

| Innovators | : PK Singh, Krishna Kumar, TVRS Shrama, Ajanta Birah, RC Srivastava |

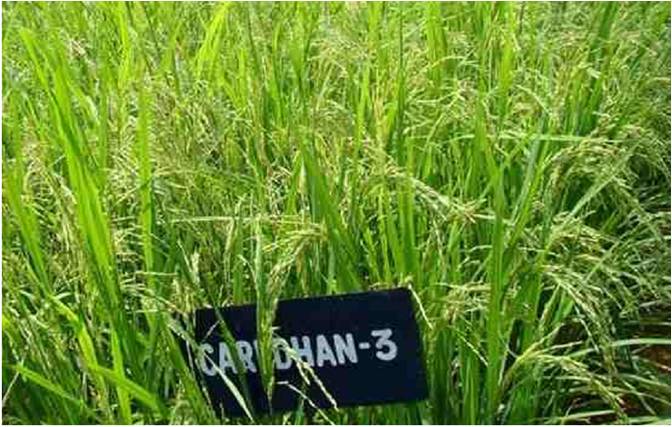

CARI DHAN3

|

Plant height (cm) | : 115 |

| Panicle length (cm) | : 25 | |

| Days to maturity | : 120 | |

| No. of tillers/plant | : 6 | |

| Grain type | : Long slender | |

| Yield | : 5 t/ha | |

| Biotic Stress | : Tolerant to Bacterial Blight and Stem Borer | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : Rainfed lowland normal soils of Andaman & Nicobar Islands. | |

| Innovators | : PK Singh, Krishna Kumar, TVRS Shrama, Ajanta Birah, RC Srivastava |

CARI DHAN4

|

Plant height (cm) | : 110 |

| Panicle length (cm) | : 25 | |

| Days to maturity | : 140 | |

| No. of tillers/plant | : 6 | |

| Grain type | : Medium Bold | |

| Yield | : 3.5 t/ha | |

| Biotic Stress | : Tolerant to Bacterial Blight, Leaf folder and Stem Borer | |

| Abiotic Stress | : Salt tolerant | |

| Area of Cultivation | : Saline soils of Andaman & Nicobar Islands. | |

| Innovators | : PK Singh, Krishna Kumar, TVRS Shrama, Ajanta Birah, RC Srivastava |

CARI DHAN5

|

Plant height (cm) | : 123 |

| Panicle length (cm) | : 24 | |

| Days to maturity | : 140 | |

| No. of tillers/plant | : 7 | |

| Grain type | : Medium Bold | |

| Yield | : 4.0 t/ha | |

| Biotic Stress | : Tolerant to Bacterial Blight, Leaf folder and Stem Borer | |

| Abiotic Stress | : Salt tolerant | |

| Area of Cultivation | : Saline soils of Andaman & Nicobar Islands. | |

| Innovators | : PK Singh, Krishna Kumar, TVRS Shrama, Ajanta Birah, RC Srivastava |

CARI Brinjal 1Variety - Crop: Vegetable

|

Plant height (cm) | : 75 |

| Days to first flowering | : 70 | |

| Fruits/Plants | : 5-7 | |

| Average fruit weight | : 170 | |

| Fruit colour | : Green | |

| Fruit shape | : Oblong | |

| Fruit Yield | : 20-25q/ha fruits | |

| Biotic Stress | : Bacterial wilt resistant germplasm | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : South, Middle and North Andaman | |

| Innovators | : Krishna Kumar, PK Singh, Ajanta Birah, Shrawan Singh, Neresh Kumar, AK Singh, DR Singh and RK Gautam |

CARI C-1 (CARI- Annapurna) Variety - Crop: Coconut

|

Salient Features | : It is a dwarf palm with large size nuts |

| : Variant of the Niu-lekha, one of the collections from Fiji Islands | ||

| : The copra out turn/palm/year - 13.70 kg | ||

| Yield | : High copra content - 245g/nut. | |

| Abiotic Stress | : Drought tolerant | |

| Area of Cultivation | : Islands Conditions | |

| Innovators | : M. Sankaran, V. Damodaran and K. Abirami |

CARI C-2 (CARI- Surya) Variety - Crop: Coconut

|

Salient Features | : Dwarf palm |

| : Crown shape is circular | ||

| : Nut shape is spherical | ||

| : Colour of the fruit is red | ||

| : Palms are dwarf with closer internodes, compressed crown and shorter petioles. | ||

| Grain type | : Medium slender | |

| Yield | : The Average no. of nuts/palm/year- 104.90. | |

| Biotic Stress | : Nil | |

| Abiotic Stress | : Drought tolerant | |

| Area of Cultivation | : Islands Conditions | |

| Innovators | : M. Sankaran, V. Damodaran and K. Abirami |

CARI C-3 (CARI- Omkar) Variety - Crop: Coconut

|

Salient Features | : It is a dwarf palm with close internodes |

| : Short petioles and compressed crown | ||

| : Semi-circular crown with less than 20 leaves on the crown. | ||

| : Nut shape is pear shape with less meat content | ||

| Yield | : The Average no. of nuts/palm/year- 110.80 | |

| Biotic Stress | : Nil | |

| Abiotic Stress | : Drought tolerant | |

| Area of Cultivation | : Islands Conditions | |

| Innovators | : M. Sankaran, V. Damodaran and K. Abirami |

CARI C-3 (CARI- Chandan) Variety - Crop: Coconut

|

Salient Features | : It is a dwarf palm with close internodes |

| : Short petioles and semi-circular compressed crown | ||

| : Nut shape is spherical and smooth without prominent ridges. | ||

| : A promising cultivar for the islands conditions and coastal ecosystem. | ||

| Yield | : The Average no. of nuts/palm/year- 98.10. | |

| Biotic Stress | : Nil | |

| Abiotic Stress | : Drought tolerant | |

| Area of Cultivation | : Islands Conditions | |

| Innovators | : M. Sankaran, V. Damodaran and K. Abirami |

CARI-SP1 (CARI-Swarna) Variety - Crop: Tuber crops

|

: The plants are spreading | |

| Emerging leaves colour | : Purple | |

| Petiole colour | : Light purple | |

| Tubers colour | : Light pink, orange fleshed. | |

| Duration | : 110-120 days | |

| Yield | : 20-21 t/ha | |

| Biotic Stress | : Resistant to Weevil | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : South, Middle and North Andaman | |

| Innovators | : T. Damodaran, D. R. Singh, R.C. Srivastava, Shrawan Singh, R. Sudha, M. Sankaran and V. Damodaran |

CARI-SP1 (CARI-Aparna) Variety - Crop: Tuber crops

|

: The plants are semi spreading | |

| Emerging leaves colour | : Light Purple | |

| Petiole colour | : Greenish pink | |

| Tubers colour | : Light pink, white fleshed. | |

| Duration | : 110-120 days | |

| Yield | : 20-21 t/ha | |

| Biotic Stress | : Modirately Resistant to Weevil | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : island Conditions | |

| Innovators | : T. Damodaran, D. R. Singh, R.C. Srivastava, Shrawan Singh, R. Sudha, M. Sankaran and V. Damodaran |

CARI-DA1 (CARI-Yamini) Variety - Crop: Tuber crops

|

Leaf Shape | : Cordate |

| Petiole colour | : Greenish pink | |

| Tubers colour | : Light pink, white fleshed. | |

| : Ideal as intercrop in the coconut and arecanut plantations. | ||

| Yield | : 40-45 t/ha | |

| Biotic Stress | :Moderately tolerant to anthracnose disease and leaf spot | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : island Conditions | |

| Innovators | : M. Sankaran, V. Damodaran and D. R. Singh |

CARI-Pretty Green Bay Orchid

|

No. of flowers/Spike | : 35-45 |

| No. of Spike/Plant | : 4-6 | |

| Spike Length | : 120-150 cm | |

| Flower size | : Small | |

| Yield | : 5 t/ha | |

| Biotic Stress | :Nil | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : Island Conditions | |

| Innovators | : D. R. Singh, R. Sudha and L. B. Singh |

CARI-Broad Dhaniya

|

No. of flowers/Spike | : 35-45 |

| No. of Spike/Plant | : 4-6 | |

| Spike Length | : 120-150 cm | |

| Flower size | : Small | |

| Yield | : 5 t/ha | |

| Biotic Stress | :Nil | |

| Abiotic Stress | : Nil | |

| Area of Cultivation | : Island Conditions | |

| Innovators | : Singh, S., Singh, D.R., Pandey, V.B., Singh, L.B., Balakrishnan, M., Nayak, H. and Ambast, S.K. |

Raised bed technology with coconut husk burial for year round Vegetable production

|

|

Raised bed with coconut husk |

Vegetables on raised bed |

Description of Technology:

Andaman and Nicobar Islands receives more than 3000 mm of rainfall in a year from May-Nov and the weather conditions are very hostile during the period. Due to heavy rains, the vegetable production is very limited in these months and there is always scarcity of vegetables. Under this method beds were raised to a height of 1 foot from the ground level with coconut husk, which was thrown as waste and again covered with soil. The vegetables can be grown on the raised bed and the furrows can be used for growing border row trap crops like Tagetus and Swamp taro.

Equipments/ Raw Materials

Space Required

Protocol

| Capital Investment | : Rs.18, 981/- for 1153 m2 |

| Net Returns | Total income/year/ha*: Rs.30000/- approx * Please note the income may vary depending upon the vegetable crops taken in beds |

| Beneficiaries | Island farmers |

| Advantages of the Technology | The areas close to the sea or low lands get flooded during heavy rains are left fallow. These lands can be effectively converted into cultivable land by the raised bed method, which helps to overcome the stress of heavy rainfall. |

| Risks Involved | Crop failure due to aberrant weather conditions |

Black Pepper cultivation on hedge rows and Gliricidia standards

|

|

Description of Technlogy:

Farmers of Andaman and Nicobar Islands are growers of spices including black pepper . A total of 29,000 ha (25,000 ha coconut + 4000 ha arecanut) of arable land (50,000 ha) in the islands are under plantation crops which provides suitable environment for the spice production. In addition 3000 ha sloppy lands are under vegetable cultivation. If one fourth of the area under plantation and sloppy lands are utilized for organic cultivation of black pepper, it is estimated to produce 2020 mt annually. The two technologies developed for black pepper cultivation are (i) Design of double hedgerows technology of black pepper cultivation and (ii) Design of black pepper cultivation on Gliricidia standards in homegarden/ coconut plantation.

Equipments/ Raw Materials

Space Required

Protocol

| Capital Investment | : Rs.67, 760/- for 6 yrs. |

| Net Returns | Cumulative income for 6 yrs Rs. 3,32,740/- |

| Beneficiaries | Island farmers |

| Advantages of the Technology | Gliricidia hedge rows system makes the cultivation of black pepper efficiently. |

| Risks Involved | Quick wilt disease of black pepper |

Cultivation of Morinda citrifolia in challenge situation

|

|

Description of Technlogy:

Morinda citrifolia L. (noni) a dwarf, perennial shrub, capable of yielding upto 40-50 years, grows slowly during first six months and starts commercial production from third year . The plant was looked upon by many during distress and disease. Thus the noni plant got a signified place of honour in several cultures making it divine entity among them. The plant for its beneficial effects for mankind was known for millenniums but recently steps are taken to popularize and commercially exploit the underutilized shrub.

Equipments/ Raw Materials

Space Required

Protocol

| Capital Investment | : Rs. 55000/- |

| Net Returns | 15000/- (3rd year) |

| Beneficiaries | Entrepreneurs like

|

Advantages of the Technology

Risks involved

Excess sea water during high tides may damage soil mounts in salt affected area, which may in turn affect the cultivation of Noni.

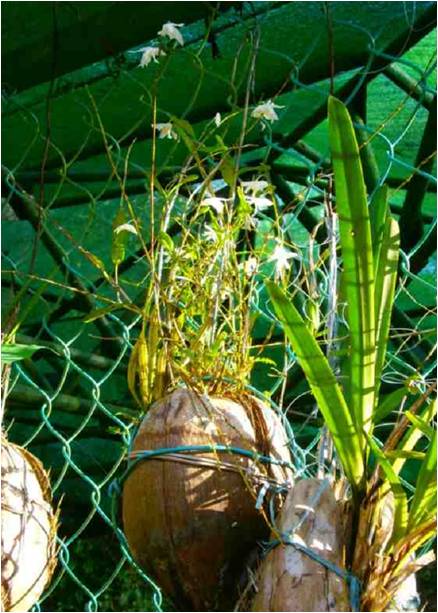

Orchids in coconut shell

|

Description of Technlogy: |

Orchids are mostly popular for their tremendous long vase life with fascinated colours. The islands have a large area (25000 ha) under coconut plantations and about 90 million nuts are produced annually. The coconut shell with growing media of broken bricks, charcoal, coconut husk in 1:1:2 ratio and with proper provision for drainage has been used successfully to grow tropical orchids viz Cymbidium bicolor , Dendrobium crumenatum, Dendrobium formosum and Oberonia iridifolia. |

Equipments/ Raw Materials

Space Required

Protocol

| Capital Investment | Rs 20 per hanging pot |

| Net Returns | Rs. 30- 40 per hanging bunch per pot |

| Beneficiaries | Entrepreneurs & Garden lovers |

| Advantages of the Technology | The coconut shells which are available in plenty in the islands are wasted without any use, which can be utilized as hanging pots after varnishing it, which enhances beauty, and prolongs life. |

| Risks Involved | The heavy sun light and intense rains may damage quality of flowers |

Backyard farming of Nicobari Fowl and Dual - Purpose poultry(Nishibari and Nicorock)

|

|

Description of Technlogy:

Nicobari fowl locally known as Takniet means short legged is a scavenging bird particularly found in Nicobar group of islands. There are three strains of Nicobari fowl viz. black, brown and white. Nicobari fowl can survive well on kitchen waste, coconut grating, insects, pests, wild seeds, grains, grasses and other vegetations. The birds can also be reared under backyard system using indigenously shelter and deep litter system of management.

Equipments/ Raw Materials

Space Required

Protocol

| Capital Investment | Rs. 1,00,000 for 100 birds |

| Net Returns | Rs. 45,000 per year |

| Beneficiaries | Island farmers & Entrepreneurs |

Advantages of the Technology

| Risks Involved | Outbreak of major poultry disease |

Azolla as a feed supplement for backyard poultry

|

|

Description of Technlogy:

Azolla is a free floating water fern used as a sustainable feed substitute for livestock and backyard poultry. Azolla can be grown and cultivable under this island ecosystem. Its nutritive value showed the feasibility of its utilization as a feed supplement for livestock and poultry.

Equipments/ Raw Materials

Space Required

Protocol

| Capital Investment | Nil |

| Net Returns | 10-50 paisa savings in feed cost per bird |

| Beneficiaries | Island farmers |

| Advantages of the Technology | Simple and low cost technology |

Risks Involved

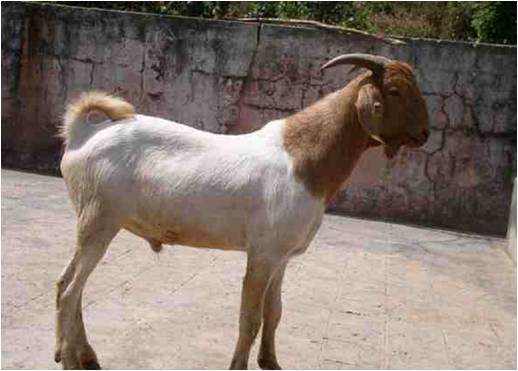

Boer cross Goat

|

|

Description of Technlogy:

Boer cross (Andaman local goat x Boer goat) goat was successfully produced through Artificial Insemination technology. The performance evaluation experiment showed successful adaptability of the new cross bred to the island ecosystem and higher body weight gain (20-40%) than the native goats at the marketable age (12 months). The performance of the upgraded goat is satisfactory. The current technology has brightened the prospects for better economic viability of goat farming and mutton availability in these Islands and created high demand for good meat breeds among the Island farmers. CIARI released and distributed boer cross bred goat to the farmers and entrepreneurs of this island for improving the livelihood / employment generation through participatory evaluation mode.

Equipments/ Raw Materials

| Space required | 10-20 sq.ft / goat |

| Protocol | Artificial insemination using frozen semen technology during natural or induced heat in desi goats. |

| Capital Investment | Total investment in 25 months is Rs. 270200 |

| Net Returns | After 25 months the net profit is Rs. 8815 with cash return of Rs. 279015 |

| Beneficiaries | Island farmers, Entrepreneurs |

Advantages of the Technology

Risks Involved

Outbreak of disease

MAT nursery

Description of Technlogy:

MAT nursery would be appropriate for rising of rice nursery in high rainfall areas. The seedlings forms mat, pulling out of seedlings, rolling and transportation is easy and less time consuming compared to traditional method.

Equipments/ Raw Materials

| Space required | 100 m2 nursery per ha |

Protocol

| Capital Investment | Rs.1566/- |

| Net Returns | In the form of savings on land (300m2 area), labor and input cost up to the tune of Rs.5000/- as compared to conventional method of wet nursery. |

| Beneficiaries | Rice farmers |

Advantages of the Technology

Risks Involved

Likely damage if not protected from heavy rains for the first 5 DAS

System of rice intensification

Description of Technlogy:

System of Rice Intensification (SRI) aims to reduce the number of seedling required to plant but gives maximum care during the growth and development. This is input intensive technology with one seedling per hill, spacing of 25 x 25 cm and 14 day old seedlings are transplanted. The critical stage is the first 20 days of transplanting. Since, bay islands receives higher intensity rainfall, single seedling might get damaged due to continuous rainfall.

Equipments/ Raw Materials

| Space required | Any available space suitable for rice cultivation. |

Protocol

| Capital Investment | Only recurring costs of inputs like seed, labour, manure, fertilizer, pesticides etc. |

| Net Returns | Rs. 5000 to 10000. |

| Beneficiaries | Rice farmers |

Advantages of the Technology

Risks Involved

Likely damage of seedlings by heavy intensive rainfall during first 20 days after transplanting.

Integrated farming system for various Micro farming situations

Description of Technlogy:

There are three situation viz., Hilly (MFS I), Slopping hilly upland (MFS II), Medium upland valley (MFS III) & Low lying valley (MFS IV). Component analysis of Integrated Farming System under various resource conditions (hilly, slopping hilly upland, Medium valley and low lying valley) indicates that cropping contributed more to net returns (69 to 83 %) in hilly and slopping hilly uplands where as livestock components (Cattle, poultry & fish) contributed more to net returns (49 to 66 %) in medium upland valley and low lying valley areas.

Equipments/ Raw Materials

| Space required | Model developed for one hectare area and can be replicated with available land at farmer's field. |

| Protocol | Vary depending on the component selection and its integration. |

| Capital Investment | Rs. 45000 to 1.5 lakhs/ha depending on farming situation and component integration. |

| Net Returns | Rs.45000 to 1.5 lakhs/ha/annum depending on farming situation and component integration. |

| Beneficiaries | Small and medium farmers |

Advantages of the Technology

Risks Involved

Nil

Broad Bed and Furrow system

|

|

Description of Technlogy:

The technology involves making of broad beds and furrows alternatively to provide drainage and standing water to the required crop viz., vegetables and rice respectively. Land manipulation made once can be kept permanently. BBF provides opportunity for better growing conditions for vegetables as they are grown on the raised beds.

| Equipments/ Raw Materials | Hitachi for land shaping. Other inputs based on crop selection in beds. |

| Space required | 10-20 sq.ft / goat |

Protocol

| Capital Investment | Rs.80000 to 1.0 lakhs /ha for land shaping. |

| Net Returns | Rs. 1.5 to 2.0 lakhs/ha/annum depending on crops grown in the beds. |

| Beneficiaries | Farmers of having waterlogged and flat valley lands. |

Advantages of the Technology

Risks Involved

Heavy rainfall during initial stages like germination to seedling stage may cause damage to the vegetables.

Dhaincha intercropping in wet seeded rice

Description of Technlogy:

Due to the fast changing scenario of rice production and marketing, farmers are encountering the problem of low returns from rice cultivation. One way is to reduce the cost of production while maintaining productivity at same level. Intercropping of green manures could be a viable strategy to counter the problem of heavy infestation of weeds in wet seeded rice. S. aculeata (dhaincha) and S. rostrata can be recommended for intercropping in wet seeded rice under island conditions. Among the two green manures, dhaincha is best suited in farmer's field.

| Equipments/ Raw Materials | Dhaincha seed at the rate of 40 to 45 kg/ha. |

| Space required | Grown as intercrop in rice paddy in alternate rows. |

Protocol

| Capital Investment | Seed cost of Rs 500 per ha |

| Net Returns | Rs. 2500 to Rs.3000 ha-1 depending upon the local wages, soil type etc. |

| Beneficiaries | Rice grower |

| Advantages of the technology | Avoidance of separate cultivation of green manure, rice nursery and of transplanting. |

| Risks Involved | Nil |

Captive seed production of damsel fish

|

|

Description of Technlogy:

The reef waters of A & N Islands harbors a variety of exportable and valuable ornamental fishes. Due to high demand of ornamental fishes, in USA, E.U. & Japan, ornamental fish breeding unit can be a profitable business proposal. The technology can be initiated with initial smaller scale with an area of 0.1 ha. The business can be initiated with an amount of 1.5 lakhs for production of 4000 -5000 seed per year

Equipments/Raw Materials

Space Required

Protocol

| Capital Investment | Rs. 1, 65,000 |

| Net Returns | Rs. 1, 06,000* * Income may vary depending upon the rate and market of ornamental fishes |

| Beneficiaries | Unemployed youth, Tsunami affected farmers, Private entrepreneurs |

Advantages of the technology

| Risks Involved | Source of foreign exchange Islands have regulations restricting live germplasm movement; hence hatchery produced marine ornamental fish juveniles cannot be sold outside the islands. |

Mud crab culture

|

|

Description of Technlogy:

The present technology can be suitable in brackish water areas where water level can be maintained around 75 cm. Grow-out ponds can be constructed in tidefed estuaries, backwaters and creeks. The crab ponds can also be established in traditional fish/ shrimp farms, by converting one portion adjoining the brackish water canal, which would help increase the overall income of traditional fish/ shrimp farmers. A 2 feet high bamboo fencing on the bund is essential to prevent escape of crabs from the pond. A pond of 0.1 ha area can be used for mud crab culture. With 500 nos /ha stocking density of 50-60g size crab for a period of six months, about 780kg/ ha production can be achieved.

Equipments/Raw Materials

Space Required

Protocol

| Capital Investment | Rs.19, 000 |

| Net Returns | Rs. 2080 per culture from 0.1 hectare pond |

| Beneficiaries | Unemployed youth, Tsunami affected farmers, Private entrepreneurs |

Advantages of the technology

Risks Involved

Small scale seed production and nursery raising of Indian Major Carps (IMC)

Description of Technlogy:

IMC & Exotic cultivable fishes mature at 2+ years of age. Potential carp brooder ranges from 2-5 kg in weight. The breeding season starts in Andaman after south west monsoon and lasts for about 3½ months. In small scale hapa breeding operation, breeding and incubation are carried out in the brood stock pond itself. During a breeding season, three times nursery management can be repeated. Production from the last nursery pond can be raised in the nursery pond itself to become fingerling or yearling. These fingerling and yearling will give an additional income to the farmer.

Equipments/Raw Materials

Space Required

Protocol

| Capital Investment | Rs. 2, 57,000/- |

| Net Returns | Rs. 1, 63,000 from second year onwards |

Beneficiaries

Advantages of the technology

Risks involved

Eulophia orchid

Description of Technlogy:

Eulophia andamanensis is an endemic green orchid in bay Islands. When it is grown in pots, it should be kept in a lath house or in open under shade (55-60%) in suitable locations. It has been evaluated and identified for its potential as potted plants owing to its good quality and other features like long spikes with many green florets.

Equipments/Raw Materials

Space Required

Protocol

| Capital Investment | Rs. 40000/- per ha |

| Net Returns | Rs. 50000- 60000 per ha per year |

| Beneficiaries | Entrepreneurs and nurseries |

| Advantages of the Technology | Being a terrestrial orchid it can be grown in grounds covered with shade and can be grown in pots in open conditions. |

| Risks Involved | Crop failure due to aberrant weather conditions. |

Gladiolus

|

|

|

Description of Technlogy:

Andaman and Nicobar Islands are emerging as one of the prominent tourist centers in the country for its scenic beauty and unique landscape. Most of the farmers were unaware about the technical knowhow and do how regarding the cultivation of gladiolus. Scientific cultivation of gladiolus including the complete package of practices stimulated the farming communities in adopting the cultivation in large scale. Recommended gladiolus varieties: Dhiraj, Urmila, African star, American beauty, Chandini.

Equipments/Raw Materials

Space Required

Protocol

| Capital Investment | Rs. 3 lakhs per ha |

| Net Returns | 4.5 to 5 lakh per ha year |

| Beneficiaries | Entrepreneurs and nurseries |

| Advantages of the Technology | Due to influx of Indian and foreign tourists to these islands, there is a great demand of cut flowers from the hotels catering to the tourists. |

Risks Involved

West Indian Cherry

Description of Technlogy:

West Indian cherry (Barbados cherry) is one of the richest source of ascorbic acid (6-8 times more than the recommended dose). Demonstration of scientific aspects of cultivation will motivate the farmers in adopting the technology on commercial scale.

Equipments/Raw Materials

| Space Required | Limited space |

| Protocol | Standard package and practices available with the Institute. Specific recommendation can be shared on demand. |

| Capital Investment | Rs. 40000/- |

| Net Returns | Rs. 20000/- |

| Beneficiaries | Island farmers |

Advantages of the Technology

| Risks Involved | The fruit marketing and processing need to be improved. |

Marigold

Description of Technlogy:

Floriculture industry has proved to be a highly profitable agro-business generating maximum returns per unit area. Many farmers grow it in small areas in their homesteads due to lack of technical knowhow and do how. Scientific cultivation of marigold by adopting improved varieties viz CO-1, Namdhari marigold, Pusa Narangi, pinching of terminal leaves for better growth and yield has encouraged the farmers in opting the scientific cultivation of marigold in large scale in the islands.

| Recommended marigold varieties | Chirakul, Pusa. |

| Equipments/Raw Materials | Quality seeds, Manures and fertilizer, Manpower & Water supply for irrigation. |

| Space Required | Owned/ rented space as per availability |

Protocol

| Capital Investment | Rs 70,700 per ha |

| Net Returns | 80000-90000 per ha |

| Beneficiaries | Nurseries and Garden lovers |

Advantages of the Technology

| Risks Involved | The heavy rains may damage the crops, so, protected structures may be used during rainy period. |

Tuberose

Description of Technlogy:

Tuberose as cut lower mainly imported from mainland market leads to exorbitant price in the local market due to huge expenses involved in air cargo. As tuberose fetches high prices in the local market many farmers grow it in small areas in their homesteads due to lack of technical knowhow and do how. Scientific cultivation of tuberose by selection of good quality planting materials of improved varieties viz. Kolkata double and Shrinagar (single) and planting at appropriate time from Nov- Dec encouraged the farmers in systematic cultivation of tuberose on large scale basis in South Andaman district.

Equipments/Raw Materials

| Space Required | Owned/ rented space as per availability |

| Protocol | Standard package and practices available with the Institute. Specific recommendation can be shared on demand. |

| Capital Investment | Rs. 60000 per ha |

| Net Returns | Rs. 70000-80000 per ha |

| Beneficiaries | Nurseries and Garden lovers |

| Advantages of the technology | Tuberose occupies a prime position because of its importance as cut flower, loose flower and its profitable cultivation due to lesser incidence of pest and disease and low input requirement. |

| Risks Involved | The heavy rains may damage the crops, so, protected structures may be used during rainy period. |

Oyster Mushroom

|

|

Description of Technlogy:

Oyster mushroom cultivation is simple, requires less materials time, labour and investment in comparison to button mushrooms. Its cultivation can be started with very low investments in home gardens or as homestead project. The main and most important ingredient for mushroom cultivation is good quality spawn which can be obtained/ procured from research laboratories/government organization/ reputed spawn production unit dealing in spawn production.

Equipments/Raw Materials

Space Required

Protocol

| Capital Investment | The total investment in 12 months is Rs. 59000/- |

| Net Returns | Rs. 49000/- from 2nd year onwards |

| Beneficiaries | Island farmers |

Advantages of the technology

| Risks Involved | Chances of contamination if not maintained properly with high standards of sanitation and sterilization of substrate and cropping room. |

CARI-MIN -Growth promoting micronutrient for pig

Description of Technlogy:

Alternate least cost fortified feed with micronutrients suitable for pig feeding. It can be used for promoting the growth in pigs . Average daily body weight gain was significantly more i.e.365.33 g than control i.e.298.8g

Materials Required

HERBAL FEED

Developed two herbal based preparation for poultry i.e. Grommune for higher growth and immunity and Morical as a feed supplements for higher egg production and quality. The feed can be used for promoting higher growth and immunity in poultry

Biomass Fired Dryer

Description of Technlogy:

A mechanical dryer with capacity of 1000 coconuts per batch was designed and fabricated using MS frame (2.4 m x 1.2 m x 1.7 m). The drying bed made of M.S bar grill kept at a height of 1.20 m above the ground level. A cylindrical shape heat exchanger was designed and fabricated using a 20 gauge metal sheet. The combustion chamber (2.5 m diameter) is made of 2 mm thick M.S. sheet. Two galvanized pipes have been connected at upper and lower side with combustion and drying chambers. A door is provided for loading and unloading of fuel. Four wheels have been provided at the base of frame for easy transport. Drying took 20 hours from an initial moisture content of 50% to a final moisture content of 6.0 % of coconut. It saves 50% of drying time as compared to natural sun drying.

| Equipments/Raw materials | Coconut husk or any biomass |

| Space required | Not applicable |

| Protocol | Not applicable |

| Capital Investment | Rs.30, 000 - 50,000 for each unit. |

| Net Returns | Using biomass fired copra dryer, the drying time is 50% less than natural sun drying in addition to making good quality copra. It helps in saving time, manpower and energy through use of coconut shell as fuel, thereby enhancing the net return to the farmers. |

| Beneficiaries | Coconut growers |

| Advantages of the Technology | The locally available biomass may be efficiently utilized as fuel for drying, and thereby enhancing net return to the farmers. |

| Risks Involved | There are chances of accidental fire if no proper supervision during drying process |

Coconut dehusker

Description of Technlogy:

Pedal and hand operated coconut dehusker have been ergonomically designed with aim to easy to operate by an unskilled farmer/farm women. The performance of CIARI designed pedal, hand operated dehusker and local tool was evaluated with different sizes of nuts at 12.5% moisture content. The dehusking capacity of dehusker was 125, 72 and 180 nuts/hr respectively for CIARI pedal operated, CIARI hand operated dehusker and local tool 'sabbal'. In case of CIARI deshuker the height can be adjusted as per operator's requirement. It was observed that the bending cycle stress /pain was experienced after dehusking of 80-90 nuts by 'sabbal', 120-130 nuts by CIARI hand operated and 150-160 nuts by pedal operated due to picking up of nuts at ground.

| Equipments/Raw materials | It is a product manufactured or fabricated. |

| Space required | Not applicable |

| Protocol | Not applicable |

| Capital Investment | Rs.1000 to 1600 for each unit. |

| Net Returns | In terms of reduced drudgery during dehusking of nuts. |

| Beneficiaries | Coconut growers |

| Advantages of the Technology | It helps the farmers to dehusk with less pain and time. |

| Risks Involved | Nil |

Value added products from mango

|

|

|

Among the fruit crops, mango is the second most important fruit both in area and production wise in Andaman. Due to diversity of mango in these islands, there is a chance of cross pollination among the varieties and it was observed that there is a off season production of mango. But the off season mangoes are not fetching good price in the market as that of main season fruits because of low quality. Hence, converting these fruits into a value added products is the reliable solution to utilize the off season mangoes in an effective way. Among the products mango leather and toffee are more attractive and fetching good price in the market. Hence, leather and toffee were prepared from mango and dried by different methods viz., dried under solar dryer, mechanical dryer and open sun drying to test the suitability.

a. Mango leather

For preparation of mango leather, uniform, matured mango fruits were washed and cut into pieces. Pulp was extracted and added 0.6g KMS/kg of pulp. This pulp was spreaded into the butter smeared trays and allowed for drying. After drying of the first layer second layer of pulp was added and repeated this till a thickness of 1cm. Drying was carried out under three different methods to a required moisture level. The prepared leather was cut into pieces, wrapped with butter paper cover and stored under ambient conditions.

b. Mango toffee

For toffee preparation, pulp was extracted from mango fruits, heated till it reaches 1/3 of the quantity. Added sugar (700g) and glucose (100g) and continuously heated till it reduced to 1/3 of the total quantity. 150 g of milk powder and butter was added and stirred continuously till the end point. After that it was spreaded into the trays and allowed for drying. The toffee thus prepared was cut into pieces and wrapped with butter paper cover for storage study. The stored samples were analyzed at fifteen days intervals for their sensory and biochemical evaluation. The results revealed that the leather dried under mechanical dryer took 10.5 hours whereas solar dryer took 15 hours for drying and 24 hours in open sun drying. The toffee dried under solar dryer took two hours for drying while open condition took 5 hours for drying. The moisture content and TSS of both the produce were decreased with the advancement of storage period while the total sugar content was increased during storage. The organoleptic evaluation of the products shows that mango toffee had excellent flavour, texture, taste and overall acceptability when compare to mango leather.

Chicken Meat Pickle

|

|

Description of Technlogy:

Prepared as a value addition to the meat of spent hen. Spent hen was slaughtered at the age of 60 weeks and approximately 500 gm meat could be dissected out from each bird. The meat was cut into optimum sized and marinated with turmeric and salt and sun dried for 10 12 hours to reduce the moisture content. A value added product of spent meat. Apart from other recipes of chicken meat this pickle can also be used.